Hyper Compressor Repair Services and Upgrades

Comprehensive Hyper Compressor Support

Cook Compression is a leader in high-pressure compressor technology, throughout the life cycle of your machine.

Our complete package of service solutions includes valve and packing case repair, plunger reconditioning, cylinder repair, troubleshooting, and performance and reliability upgrades. In all cases, component reconditioning meets or exceeds original manufacturer specifications and rigorous inspection requirements.

Hyper Cups

Over decades of design and supply, Cook Compression has developed processes to improve the life of hyper cups and reduce the chance of stress failure in service.

Cook Compression hyper cups are designed so that the highest stressed portions remain in compression during the discharge stroke. The inner and outer rings of these compound cups feature an interference fit that keeps the outer ring in tension and the inner ring in compression. After assembly, the cup faces are lapped to a flatness of two light bands, and all radii and hole surfaces receive super finishing.

Cook Compression also designs and manufactures high-performance parts in proprietary designs and metallurgies.

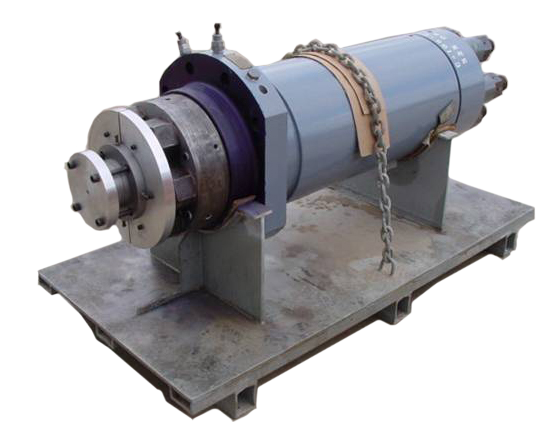

Hyper Cylinder Repair

Among the specialties of Cook Compression is the repair and reconditioning of cylinders in low-density polyethylene (LDPE) and other high-pressure services. Experienced technicians perform complete disassembly, inspection, component replacement, reassembly and pressure testing.